Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information > Reselection of knowledge

update date:2023-07-16 03:14:01Number of views: author:huang

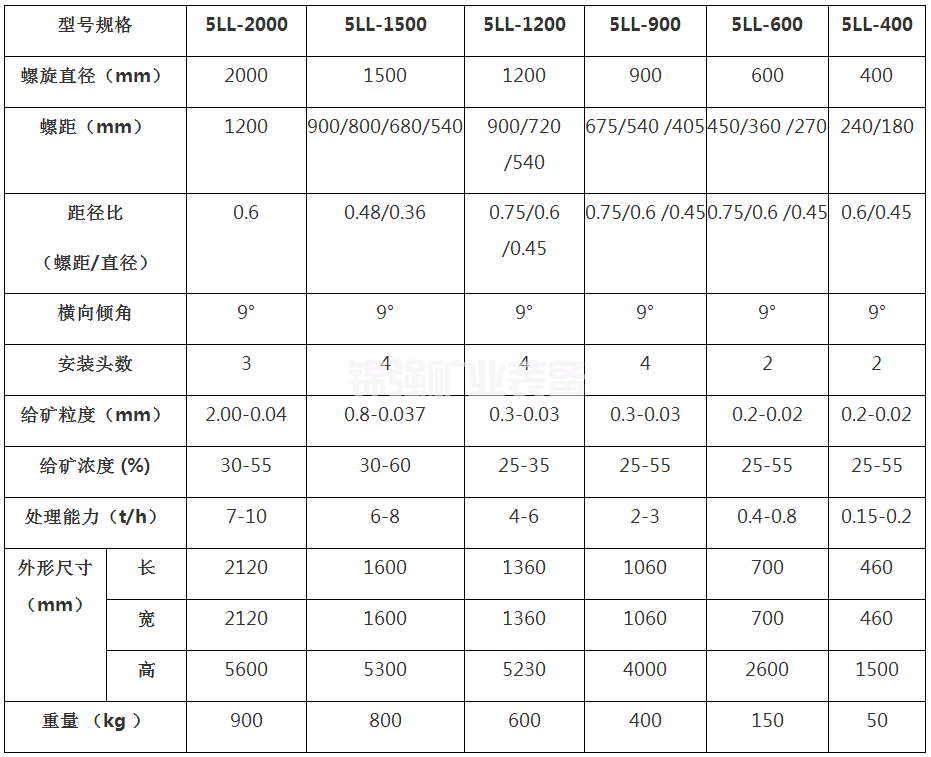

Closed spiral chute 1. Introduction: The chute beneficiation belongs to the slope flow beneficiation process. Mortar is fed to some inclined grooves or slopes, and under the push of water flow, the mineral particle group is loose and layered. The upper layer of light minerals quickly flows out of the groove, while the lower layer of minerals with high specific gravity are trapped inside the groove or discharged from the bottom at a low speed. After separation and collection, selected minerals and tailings can be obtained. The spiral concentrator is a machine for mining and beneficiation, making it ideal for mining ore in bays, river beds, sand banks, and streams. The equipment has the characteristics of correct structure, simple installation, small land occupation, simple operation, stable beneficiation, clear separation, large processing volume, high efficiency, high beneficiation enrichment ratio, high recycling rate, and reliable operation. It has the advantages of light weight, moisture resistance, rust prevention, corrosion resistance, and strong adaptability to fluctuations in feed volume, concentration, particle size, and grade. 2、 The working principle is that mortar, like a closed spiral chute, is slowly fed to the surface of the spiral chute by installing a feeding chute at the end of the rotating groove head, and sorting is carried out. The tail of the rotating groove is equipped with a valve type product selection groove, which divides the selection equipment into three types according to grade along the radial direction. By adjusting the orientation of the valve block to change the cutting width of each product, the equipment gathering hopper allows the obtained multi-directional mineral flow to be collected and led out separately. The cross-section of the spiral chute, with a slope change of ten thousand, is suitable for the separation of fine particle materials.  closed spiral chute. 3、 Due to low power consumption, simple structure, less land occupation, simple operation, stable beneficiation, clear ore screening, no need for moving parts, convenient Computerized maintenance management system, large handling capacity per unit size and other characteristics, the special spiral concentrator is more concerned in various gravity separation equipment. Machinery with wider or flatter groove surfaces and larger areas of laminar flow of ore slurry are more suitable for processing medium to fine (-4mm) ore particles. Fiberglass spiral chutes with diameters of 400, 600, 900, and 1200MM have been produced domestically, Ф The processing output of 1200mm four heads is about 4-6 tons/hour. Closed spiral chute

closed spiral chute. 3、 Due to low power consumption, simple structure, less land occupation, simple operation, stable beneficiation, clear ore screening, no need for moving parts, convenient Computerized maintenance management system, large handling capacity per unit size and other characteristics, the special spiral concentrator is more concerned in various gravity separation equipment. Machinery with wider or flatter groove surfaces and larger areas of laminar flow of ore slurry are more suitable for processing medium to fine (-4mm) ore particles. Fiberglass spiral chutes with diameters of 400, 600, 900, and 1200MM have been produced domestically, Ф The processing output of 1200mm four heads is about 4-6 tons/hour. Closed spiral chute  4. Structural composition. The fiberglass spiral chute is composed of six parts: a feeding homogenizer, a feeding chute, a spiral groove, a product cutting groove, an equipment gathering hopper or groove support (including a cross or triangular frame). The rotating groove connected by the rotating disc is a key component. The spiral plate is made of fiberglass (fiber reinforced coal gangue) and connected together by bolts. The sorting surface of the spiral groove has a pre made durable and wear-resistant layer. He also has the advantages of lightweight, strong, and durable consumables. The head of the rotating groove is equipped with a multi tube feeding homogenizer to sort minerals evenly, which is easy to control. The ore separator is not restricted from being placed on the cross (or tripod) of the support table. The evenly distributed mortar is slowly fed onto the surface of the rotating groove through a feeding groove installed at the end of the spiral groove head, and selected for operation. The tail end of the spiral groove is installed in a valve block type new product selection groove, allowing the sorting equipment to be divided into three types (or four types) of new products along the radial direction according to grade. Change the acquisition width of each new product by adjusting the position of the valve block. The new equipment gathering bucket is a concentric circular tube that converges and leads out the intercepted multiple ore flows. The lateral plane of the spiral concentrator and the change in slope of the curve are particularly suitable for the selection of small particle ore materials. 5、 Use: closed spiral chute This machine is suitable for separating iron, ferrotitanium, ferrochrome, ferrosulfide, zircon, Rutile, monazite, phosphate rock, tungsten ore, tin, tantalum niobium, tantalum niobium and other non-ferrous metal ores, rare ore metals and non-metallic minerals with specific gravity difference. Closed spiral chute

4. Structural composition. The fiberglass spiral chute is composed of six parts: a feeding homogenizer, a feeding chute, a spiral groove, a product cutting groove, an equipment gathering hopper or groove support (including a cross or triangular frame). The rotating groove connected by the rotating disc is a key component. The spiral plate is made of fiberglass (fiber reinforced coal gangue) and connected together by bolts. The sorting surface of the spiral groove has a pre made durable and wear-resistant layer. He also has the advantages of lightweight, strong, and durable consumables. The head of the rotating groove is equipped with a multi tube feeding homogenizer to sort minerals evenly, which is easy to control. The ore separator is not restricted from being placed on the cross (or tripod) of the support table. The evenly distributed mortar is slowly fed onto the surface of the rotating groove through a feeding groove installed at the end of the spiral groove head, and selected for operation. The tail end of the spiral groove is installed in a valve block type new product selection groove, allowing the sorting equipment to be divided into three types (or four types) of new products along the radial direction according to grade. Change the acquisition width of each new product by adjusting the position of the valve block. The new equipment gathering bucket is a concentric circular tube that converges and leads out the intercepted multiple ore flows. The lateral plane of the spiral concentrator and the change in slope of the curve are particularly suitable for the selection of small particle ore materials. 5、 Use: closed spiral chute This machine is suitable for separating iron, ferrotitanium, ferrochrome, ferrosulfide, zircon, Rutile, monazite, phosphate rock, tungsten ore, tin, tantalum niobium, tantalum niobium and other non-ferrous metal ores, rare ore metals and non-metallic minerals with specific gravity difference. Closed spiral chute Closed spiral chute

The difference between energy-saving bal

The difference between energy-saving bal The drawbacks of difficult selection and

The drawbacks of difficult selection and Introduction to the characteristics of d

Introduction to the characteristics of d Types of mining magnetic separation equi

Types of mining magnetic separation equi What is the price of the Hesha magnetic

What is the price of the Hesha magnetic  The dry magnetic separator is applicable

The dry magnetic separator is applicable The price of dry magnetic separators is

The price of dry magnetic separators is  Selection range of fly ash magnetic sepa

Selection range of fly ash magnetic sepa Magnetic field intensity division of mag

Magnetic field intensity division of mag Different factors affecting the price of

Different factors affecting the price of How to achieve better magnetic separatio

How to achieve better magnetic separatio Industrial types and requirements of man

Industrial types and requirements of man Cement grinding process flow of ball mil

Cement grinding process flow of ball mil Optimization and Improvement of Wollasto

Optimization and Improvement of Wollasto Production process and main equipment of

Production process and main equipment of Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete equipment for quartz sand benef

Complete equipment for quartz sand benef Complete equipment for graphite ore bene

Complete equipment for graphite ore bene Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete set of mining beneficiation equ

Complete set of mining beneficiation equ Complete energy-saving beneficiation equ

Complete energy-saving beneficiation equ Complete set of manganese ore beneficiat

Complete set of manganese ore beneficiat Gold selection complete equipment

Gold selection complete equipment Complete beneficiation equipment

Complete beneficiation equipment Complete set of sand gold beneficiation

Complete set of sand gold beneficiation  Complete set of Baryte beneficiation equ

Complete set of Baryte beneficiation equ Complete beneficiation equipment for cop

Complete beneficiation equipment for cop Complete set of iron ore equipment

Complete set of iron ore equipment Complete machine for iron ore beneficiat

Complete machine for iron ore beneficiat Complete beneficiation production line

Complete beneficiation production line