Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information > Reselection of knowledge

update date:2023-07-16 03:14:18Number of views: author:huang

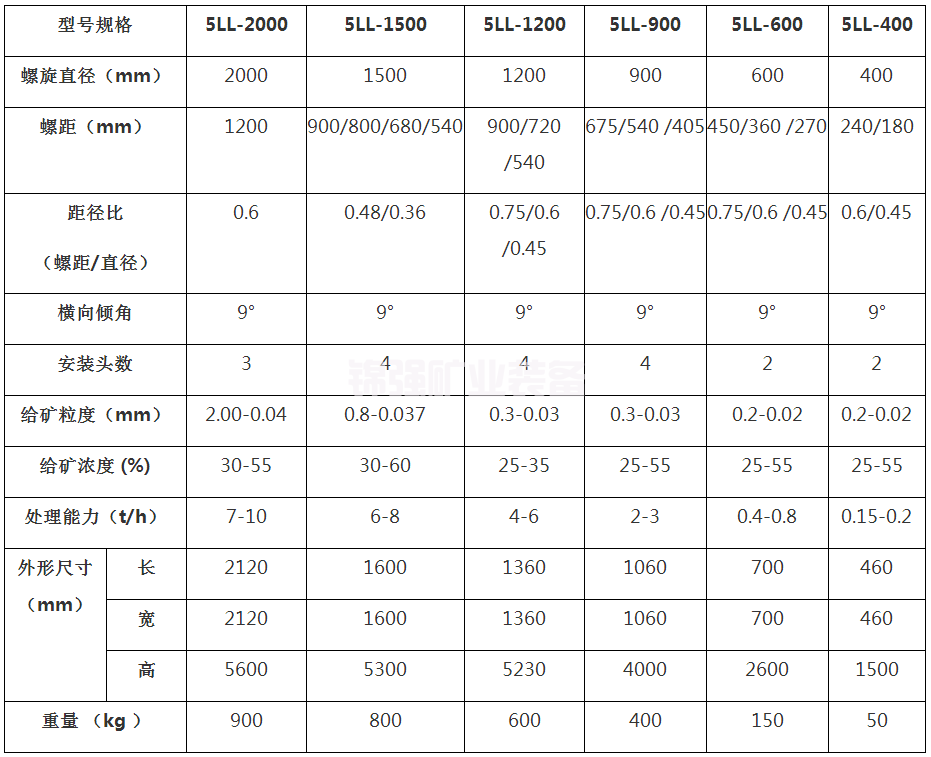

Titanium iron spiral chute 1. Explanation: Titanium iron spiral chute gravity beneficiation is widely used in the beneficiation of metal or non-ferrous metal ores due to its low pollution and low cost. The spiral concentrator is one of the gravity separation machines, characterized by a cubic parabola shaped cross-section, suitable for processing finer particle sizes of -0.2 millimeters. In the sorting process, no flushing water is required, and the tailings are obtained by dividing them into sections at the tail end of the tank. 2、 Technical principles. The uniform mineral mortar is slowly fed onto the surface of the rotating groove through the feeding chute installed at the end of the spiral groove head, and sorting is carried out. The bottom of the spiral groove is equipped with a valve block type product selection groove, which divides the selected equipment into three categories according to grade along the radial direction. By adjusting the orientation of the valve block to change the cutting width of each product, the equipment gathering bucket allows the obtained variable mineral flow to converge and lead out. The change in slope of the curve on the transverse surface of the fiberglass chute is particularly applicable for the sorting of fine-grained materials.  titanium iron spiral chute 3. Advantages and characteristics: 1. High efficiency, high recovery rate, and correct mineral sorting; 2. No power required; 3. Small weight, anti rust, durable, anti wear, and strong corrosion resistance. Titanium iron spiral chute 4 has low operating cost and long service life; 5. Strong adaptability to fluctuation of feed volume, density, Granularity and grade; The frictional force formed on the surface of 6 diamond sand makes the beneficiation efficiency better than other plastic surfaces. Titanium iron spiral chute

titanium iron spiral chute 3. Advantages and characteristics: 1. High efficiency, high recovery rate, and correct mineral sorting; 2. No power required; 3. Small weight, anti rust, durable, anti wear, and strong corrosion resistance. Titanium iron spiral chute 4 has low operating cost and long service life; 5. Strong adaptability to fluctuation of feed volume, density, Granularity and grade; The frictional force formed on the surface of 6 diamond sand makes the beneficiation efficiency better than other plastic surfaces. Titanium iron spiral chute  . 4、 The chute can be divided into three types according to the Granularity of the processed ore materials: (1) Coarse grained chute. The maximum feeding particle size is more than 2-3mm, and the maximum feeding particle size is 100-200mm. (2) The ore chute handles 2-3mm sized ore. (3) Slime chute, feeding Granularity is less than 0.074MM. 5、 Field of use. Fiberglass spiral chutes are suitable for processing 0.6-0.03 millimeters and vein ore as well as sand ore, but they are unfavorable for sorting when the mud content is high. Nowadays, it has been widely used for processing iron ore, tungsten, tin ore, tantalum niobium ore, coastal and riverbed ore, or gold ore. Titanium iron spiral chute

. 4、 The chute can be divided into three types according to the Granularity of the processed ore materials: (1) Coarse grained chute. The maximum feeding particle size is more than 2-3mm, and the maximum feeding particle size is 100-200mm. (2) The ore chute handles 2-3mm sized ore. (3) Slime chute, feeding Granularity is less than 0.074MM. 5、 Field of use. Fiberglass spiral chutes are suitable for processing 0.6-0.03 millimeters and vein ore as well as sand ore, but they are unfavorable for sorting when the mud content is high. Nowadays, it has been widely used for processing iron ore, tungsten, tin ore, tantalum niobium ore, coastal and riverbed ore, or gold ore. Titanium iron spiral chute Titanium iron spiral chute

The difference between energy-saving bal

The difference between energy-saving bal The drawbacks of difficult selection and

The drawbacks of difficult selection and Introduction to the characteristics of d

Introduction to the characteristics of d Types of mining magnetic separation equi

Types of mining magnetic separation equi What is the price of the Hesha magnetic

What is the price of the Hesha magnetic  The dry magnetic separator is applicable

The dry magnetic separator is applicable The price of dry magnetic separators is

The price of dry magnetic separators is  Selection range of fly ash magnetic sepa

Selection range of fly ash magnetic sepa Magnetic field intensity division of mag

Magnetic field intensity division of mag Different factors affecting the price of

Different factors affecting the price of How to achieve better magnetic separatio

How to achieve better magnetic separatio Industrial types and requirements of man

Industrial types and requirements of man Cement grinding process flow of ball mil

Cement grinding process flow of ball mil Optimization and Improvement of Wollasto

Optimization and Improvement of Wollasto Production process and main equipment of

Production process and main equipment of Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete equipment for quartz sand benef

Complete equipment for quartz sand benef Complete equipment for graphite ore bene

Complete equipment for graphite ore bene Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete set of mining beneficiation equ

Complete set of mining beneficiation equ Complete energy-saving beneficiation equ

Complete energy-saving beneficiation equ Complete set of manganese ore beneficiat

Complete set of manganese ore beneficiat Gold selection complete equipment

Gold selection complete equipment Complete beneficiation equipment

Complete beneficiation equipment Complete set of sand gold beneficiation

Complete set of sand gold beneficiation  Complete set of Baryte beneficiation equ

Complete set of Baryte beneficiation equ Complete beneficiation equipment for cop

Complete beneficiation equipment for cop Complete set of iron ore equipment

Complete set of iron ore equipment Complete machine for iron ore beneficiat

Complete machine for iron ore beneficiat Complete beneficiation production line

Complete beneficiation production line