Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information > Reselection of knowledge

update date:2023-07-16 03:14:38Number of views: author:huang

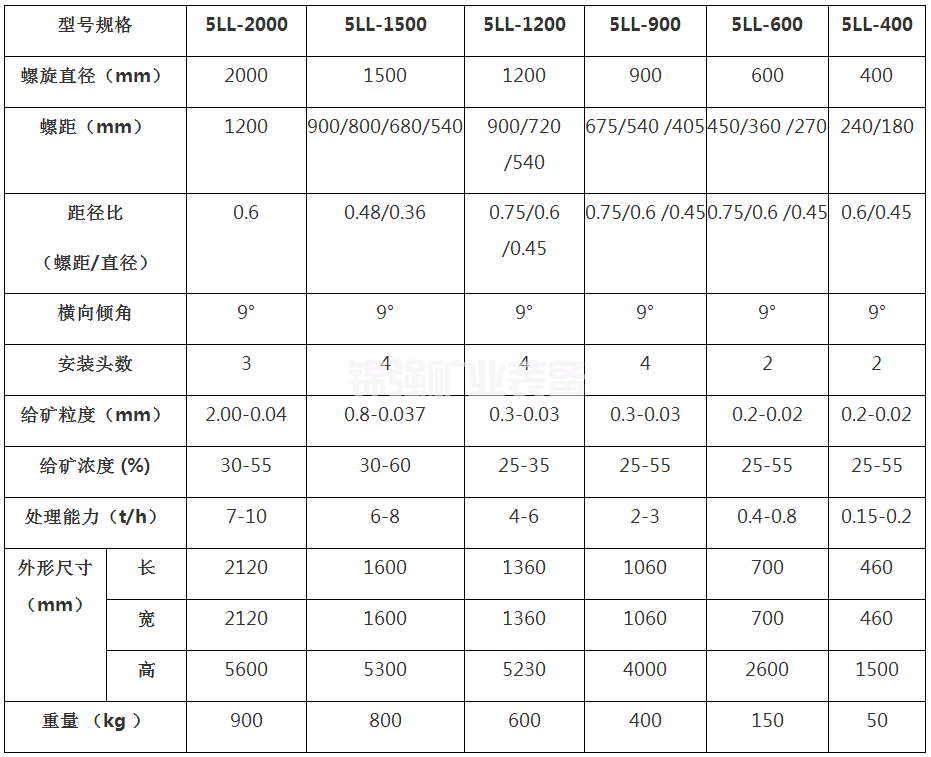

Customization of Small Spiral Chutes 1. Description: The spiral concentrator summarizes the characteristics of gravity beneficiation spiral chutes, fiberglass spiral chutes, shakers, and centrifugal gold concentrators. After scientific research organized by the Ministry of Metallurgy, appraisal conducted by departments such as design, universities, and concentrators, it has been recognized as having excellent performance, advanced sorting indicators, and has been awarded the Science and Technology Research Achievement Award by the Ministry of Metallurgical Industry. It is now in the field of non-ferrous metals Ferrous is widely used. This machine is applicable to sorting iron ore, ilmenite, chromite, pyrite, zircon sand, Rutile, monazite, phosphorus ethyl, tungsten, cassiterite, tantalum, niobium of 0.3-0.02 mm fine materials, and other non-ferrous metals, rare mineral metals or non-metallic minerals with gravity difference. 2、 The use method is to erect the glass fiber reinforced plastic spiral chute, calibrate the vertical line, fix it in an appropriate position with an iron frame or wood, send the ore sand to the two ore feeding ports above the spiral by the sand pump, mix in the make-up water, and adjust the concentration of the ore slurry. The ore slurry naturally swirls from high to low, generating a single coherent centrifugal force in the flow speed of the revolving inclined surface, so as to obtain the difference in the specific gravity, Granularity and state of the placer, Through the effect of gravity and centrifugal force obtained through swirling flow, the sand ore is separated, and the concentrate flows into the beneficiation hopper and is connected out through pipelines. The tailings are discharged into the tailings hopper and connected to the sand pit through pipelines, and then discharged by a slurry pump, completing the entire beneficiation process.  Customized small spiral chutes III. The characteristics of FRP chutes, such as low energy consumption, simple structure, small area occupation, simple operation, stable beneficiation, clear ore separation, no moving parts, convenient Computerized maintenance management system, and strong handling capacity per unit area, have attracted much attention among many gravity separation machines. The equipment has a relatively wide and stable groove surface, and the area where the slurry flows in a laminar flow is large, making it more suitable for processing medium to fine (-4mm) ore particles. China has made spiral chutes with diameters of 400, 600, 900, and 1200mm, Ф The processing capacity of 1200MM four head is about 4-6 tons/hour. Customization of small spiral chutes:

Customized small spiral chutes III. The characteristics of FRP chutes, such as low energy consumption, simple structure, small area occupation, simple operation, stable beneficiation, clear ore separation, no moving parts, convenient Computerized maintenance management system, and strong handling capacity per unit area, have attracted much attention among many gravity separation machines. The equipment has a relatively wide and stable groove surface, and the area where the slurry flows in a laminar flow is large, making it more suitable for processing medium to fine (-4mm) ore particles. China has made spiral chutes with diameters of 400, 600, 900, and 1200mm, Ф The processing capacity of 1200MM four head is about 4-6 tons/hour. Customization of small spiral chutes:  4. Construction of fiberglass spiral chutes consists of a feeding device, a cross (tripod), a feeding chute, a spiral chute, a receiving chute, a gathering bucket, and a trough support. 5、 Scope of use: FRP spiral chute is suitable for separating fine grain iron, ferrotitanium, ferrochrome, pyrite, cassiterite, tantalum niobium, gold, coal, monazite, Rutile, zircon ore, rare earth ore or other metal and non nonferrous metal minerals with sufficient specific gravity difference. Customization of small spiral chutes

4. Construction of fiberglass spiral chutes consists of a feeding device, a cross (tripod), a feeding chute, a spiral chute, a receiving chute, a gathering bucket, and a trough support. 5、 Scope of use: FRP spiral chute is suitable for separating fine grain iron, ferrotitanium, ferrochrome, pyrite, cassiterite, tantalum niobium, gold, coal, monazite, Rutile, zircon ore, rare earth ore or other metal and non nonferrous metal minerals with sufficient specific gravity difference. Customization of small spiral chutes  Customization of small spiral chutes

Customization of small spiral chutes

The difference between energy-saving bal

The difference between energy-saving bal The drawbacks of difficult selection and

The drawbacks of difficult selection and Introduction to the characteristics of d

Introduction to the characteristics of d Types of mining magnetic separation equi

Types of mining magnetic separation equi What is the price of the Hesha magnetic

What is the price of the Hesha magnetic  The dry magnetic separator is applicable

The dry magnetic separator is applicable The price of dry magnetic separators is

The price of dry magnetic separators is  Selection range of fly ash magnetic sepa

Selection range of fly ash magnetic sepa Magnetic field intensity division of mag

Magnetic field intensity division of mag Different factors affecting the price of

Different factors affecting the price of How to achieve better magnetic separatio

How to achieve better magnetic separatio Industrial types and requirements of man

Industrial types and requirements of man Cement grinding process flow of ball mil

Cement grinding process flow of ball mil Optimization and Improvement of Wollasto

Optimization and Improvement of Wollasto Production process and main equipment of

Production process and main equipment of Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete equipment for quartz sand benef

Complete equipment for quartz sand benef Complete equipment for graphite ore bene

Complete equipment for graphite ore bene Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete set of mining beneficiation equ

Complete set of mining beneficiation equ Complete energy-saving beneficiation equ

Complete energy-saving beneficiation equ Complete set of manganese ore beneficiat

Complete set of manganese ore beneficiat Gold selection complete equipment

Gold selection complete equipment Complete beneficiation equipment

Complete beneficiation equipment Complete set of sand gold beneficiation

Complete set of sand gold beneficiation  Complete set of Baryte beneficiation equ

Complete set of Baryte beneficiation equ Complete beneficiation equipment for cop

Complete beneficiation equipment for cop Complete set of iron ore equipment

Complete set of iron ore equipment Complete machine for iron ore beneficiat

Complete machine for iron ore beneficiat Complete beneficiation production line

Complete beneficiation production line