Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information > Reselection of knowledge

update date:2023-07-16 03:15:41Number of views: author:huang

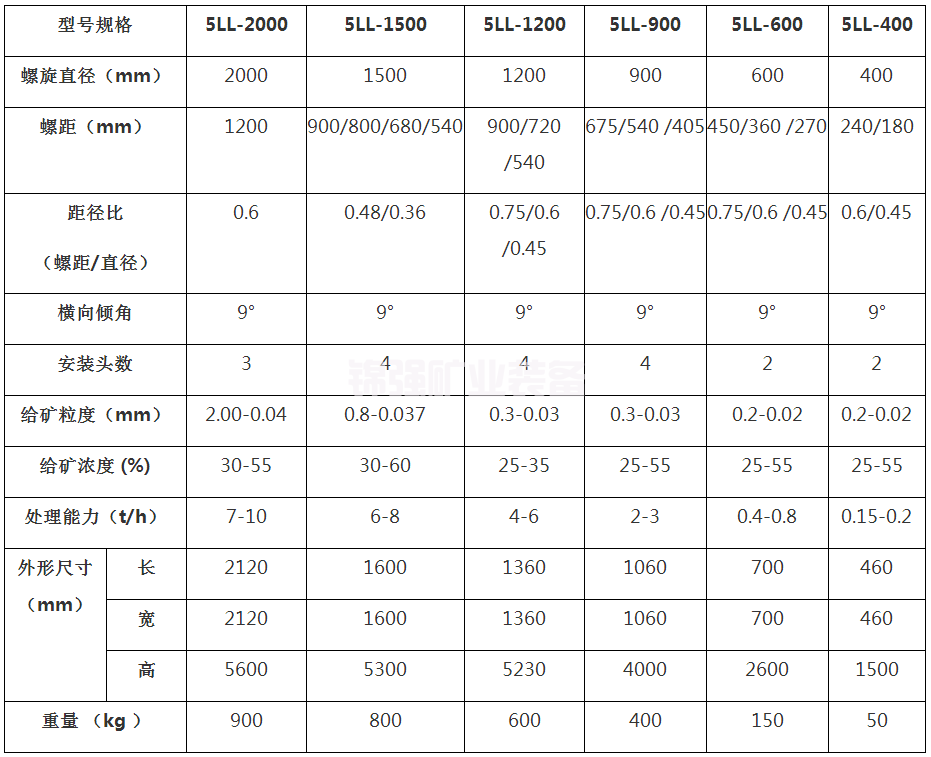

The spiral chute specification parameter table 1 shows that the spiral chute is a combination of the characteristics of the spiral concentrator, gravity spiral chute, shaking table and gold concentrator. After the relevant scientific research organized by the Ministry of Metallurgical Industry, and the operation appraisal of the design, universities, concentrators and other units, it is believed that the mechanical performance is excellent, the separation goal is improved, and it has won the scientific research achievement award of the Ministry of Metallurgical Industry. It has been widely used in non-ferrous and Ferrous mines. This equipment is used to separate iron ore, ilmenite, chromite, pyrite, zircon, Rutile, monazite, phosphorus, tungsten, tin, tantalum niobium, niobium and other non-ferrous metal ores, rare metals and non-metallic minerals with gravity difference from fine materials with a particle size of 0.3-0.02 mm. 2、 Operating principle: The spiral concentrator does not need to be restricted to placing the mineral separator on the cross (or tripod) of the support table. The same slurry is slowly fed to the rotating groove surface through the feeding groove on the spiral groove head, and sorting is carried out. The bottom is equipped with a valve block type product selection slot, which divides the selected equipment into three types (or four types) according to grade along the radial direction. Change the cutting width of each product by adjusting the position of the valve block. The equipment gathering bucket is a concentric circular tube that allows the obtained multi-directional mineral flow to be densely drawn out. The transverse surface of the spiral chute and the slope change of the curve are extremely suitable for the selection of fine particle materials. Table 3: Characteristics and Advantages of the Spiral Chute at  : 1. Superlarge-scale, large processing capacity, modern mineral processing objectively requires scale to create benefits. 2. Fine granulation: for the treatment of fine minerals, especially for the treatment of ores with a particle size of -0.047mm, the original machine can generally ensure the recovery of+0.047mm Granularity. 3. With the development of Hydraulics, two-phase flow, equipment vibration, etc., GRP chutes have developed from simple use of gravity and water blocking force to composite use of centrifugal force, mechanical vibration force, magnetic separation force, etc. Through a composite force field, the enrichment of applicable minerals and the separation of fine particles from these fine particles are enhanced, thereby improving the recovery rate of ore materials. 4. The basic starting point is to save energy, reduce energy consumption and protect the environment. The area and space occupied should be small, and the water and electricity consumption should be small. 5. Simple and flexible operation, stable sorting steps, simple structure, convenient for Computerized maintenance management system. Spiral chute specification parameter table

: 1. Superlarge-scale, large processing capacity, modern mineral processing objectively requires scale to create benefits. 2. Fine granulation: for the treatment of fine minerals, especially for the treatment of ores with a particle size of -0.047mm, the original machine can generally ensure the recovery of+0.047mm Granularity. 3. With the development of Hydraulics, two-phase flow, equipment vibration, etc., GRP chutes have developed from simple use of gravity and water blocking force to composite use of centrifugal force, mechanical vibration force, magnetic separation force, etc. Through a composite force field, the enrichment of applicable minerals and the separation of fine particles from these fine particles are enhanced, thereby improving the recovery rate of ore materials. 4. The basic starting point is to save energy, reduce energy consumption and protect the environment. The area and space occupied should be small, and the water and electricity consumption should be small. 5. Simple and flexible operation, stable sorting steps, simple structure, convenient for Computerized maintenance management system. Spiral chute specification parameter table  IV. According to the particle size of the ore being processed, the chute can be divided into three categories: (1) Coarse grained chute, with a maximum particle size of 2-3 millimeters or more for ore feeding, and a maximum of 100-200mm. (2) The ore sand chute is used to handle 2-3 millimeter sized ore materials. (3) Slurry chute, feeding Granularity is less than 0.074MM. 5、 Application field: FRP chute is suitable for separating fine iron ore, Ilmenite, Chromite, pyrite, tin ore, tantalum niobium ore, placer gold, coal mine, monazite ore, Rutile ore, zircon ore, rare earth ore, and other metal and non-ferrous metal minerals with completely enough density ratio difference. Spiral Chute Specification Parameter Table

IV. According to the particle size of the ore being processed, the chute can be divided into three categories: (1) Coarse grained chute, with a maximum particle size of 2-3 millimeters or more for ore feeding, and a maximum of 100-200mm. (2) The ore sand chute is used to handle 2-3 millimeter sized ore materials. (3) Slurry chute, feeding Granularity is less than 0.074MM. 5、 Application field: FRP chute is suitable for separating fine iron ore, Ilmenite, Chromite, pyrite, tin ore, tantalum niobium ore, placer gold, coal mine, monazite ore, Rutile ore, zircon ore, rare earth ore, and other metal and non-ferrous metal minerals with completely enough density ratio difference. Spiral Chute Specification Parameter Table  Spiral Chute Specification Parameter Table

Spiral Chute Specification Parameter Table

The difference between energy-saving bal

The difference between energy-saving bal The drawbacks of difficult selection and

The drawbacks of difficult selection and Introduction to the characteristics of d

Introduction to the characteristics of d Types of mining magnetic separation equi

Types of mining magnetic separation equi What is the price of the Hesha magnetic

What is the price of the Hesha magnetic  The dry magnetic separator is applicable

The dry magnetic separator is applicable The price of dry magnetic separators is

The price of dry magnetic separators is  Selection range of fly ash magnetic sepa

Selection range of fly ash magnetic sepa Magnetic field intensity division of mag

Magnetic field intensity division of mag Different factors affecting the price of

Different factors affecting the price of How to achieve better magnetic separatio

How to achieve better magnetic separatio Industrial types and requirements of man

Industrial types and requirements of man Cement grinding process flow of ball mil

Cement grinding process flow of ball mil Optimization and Improvement of Wollasto

Optimization and Improvement of Wollasto Production process and main equipment of

Production process and main equipment of Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete equipment for quartz sand benef

Complete equipment for quartz sand benef Complete equipment for graphite ore bene

Complete equipment for graphite ore bene Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete set of mining beneficiation equ

Complete set of mining beneficiation equ Complete energy-saving beneficiation equ

Complete energy-saving beneficiation equ Complete set of manganese ore beneficiat

Complete set of manganese ore beneficiat Gold selection complete equipment

Gold selection complete equipment Complete beneficiation equipment

Complete beneficiation equipment Complete set of sand gold beneficiation

Complete set of sand gold beneficiation  Complete set of Baryte beneficiation equ

Complete set of Baryte beneficiation equ Complete beneficiation equipment for cop

Complete beneficiation equipment for cop Complete set of iron ore equipment

Complete set of iron ore equipment Complete machine for iron ore beneficiat

Complete machine for iron ore beneficiat Complete beneficiation production line

Complete beneficiation production line