Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information > Reselection of knowledge

update date:2023-07-16 03:16:59Number of views: author:huang

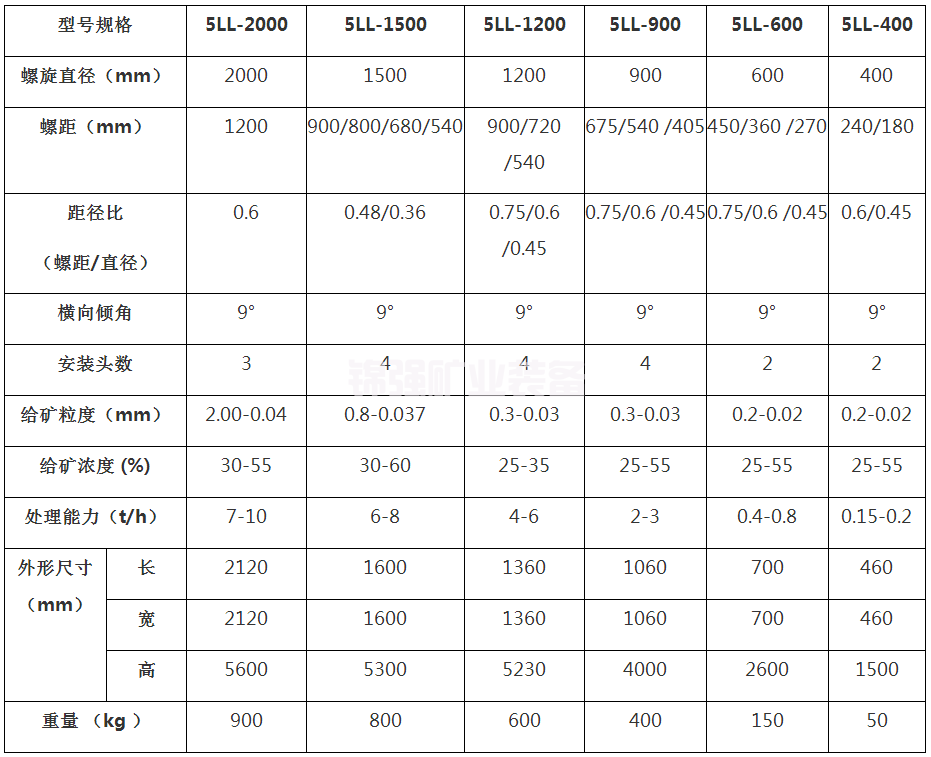

Spiral chute measurement: Spiral chute measurement: 1. Overview of chute sorting, including inclined flow sorting process. The slurry is fed to a inclined groove or inclined surface with a certain inclination. With the assistance of flowing water, the ore particles are loose and layered. The upper layer of light mineral materials are quickly discharged to the outside of the groove, while the lower layer of minerals with a larger proportion are stagnant inside the groove or slowly discharged from the lower part. After the difference is connected, the selected ore and tailings can be obtained. Spiral chutes are mining and beneficiation machinery, making them ideal for sand mining and beneficiation in coastal areas, rivers, beaches, and streams. The product also has the characteristics of suitable structure, simple installation, small footprint, easy operation, stable beneficiation, clear beneficiation, strong processing capacity, high efficiency beneficiation concentration ratio, high recovery rate, and stable operation. It has the advantages of small weight, moisture prevention, rust prevention, durability and corrosion resistance, and strong adaptability to fluctuations in feed volume or density, Granularity, and grade. 2、 Set up the spiral concentrator by using the method, calibrate the vertical line, fix the iron frame or wood at a suitable position, send the sand ore to the two ore inlets on the spiral top by the sand pump, add water, and adjust the concentration of the mineral slurry. The mineral slurry naturally swirls from high to low, generating a coherent centrifugal force in the flow rate of the whirling inclined surface, and obtaining the difference in the density, specific gravity, Granularity and shape of the mineral sand, Through the influence of the gravity of the swirling flow and the centrifugal force, the ore and sand are separated. The selected ore flows into the concentrate hopper and is piped out, while the tailings flow into the tailings hopper and are moved to the sand pit through a pipeline. Then, they are discharged by a sand pump, completing the entire beneficiation process. Spiral chute measurement 3. Features 1. Stable and simple control of sorting process 2. Large allowable variation range of ore feed concentration 3. High enrichment ratio and high recycling rate 4. Small land area occupied and low water consumption 5. Simple structure, no power required 6. Strong processing capacity 7. Easy installation and operation 8. Low investment, quick spiral chute measurement

4. Ore Granularity obtained by classification, Chutes can be divided into three categories: (1) Coarse grained chutes. The maximum Granularity of the feed is more than 2-3 mm, and the maximum can reach 100-200 mm. (2) The ore chute is used to handle 2-3mm sized ore materials. (3) Slurry chute, with a feeding particle size less than 0.074MM. 5、 Purpose This equipment is suitable for separating iron, ferrotitanium, ferrochrome, ferrosulfide, zircon, Rutile, monazite, phosphorus ethyl, tungsten sand, tin ore, tantalum, niobium ore and other non-ferrous metals, rare mineral metals and non-ferrous metal minerals with gravity difference from fine materials with Granularity of 0.3-0.02mm. Measurement of

4. Ore Granularity obtained by classification, Chutes can be divided into three categories: (1) Coarse grained chutes. The maximum Granularity of the feed is more than 2-3 mm, and the maximum can reach 100-200 mm. (2) The ore chute is used to handle 2-3mm sized ore materials. (3) Slurry chute, with a feeding particle size less than 0.074MM. 5、 Purpose This equipment is suitable for separating iron, ferrotitanium, ferrochrome, ferrosulfide, zircon, Rutile, monazite, phosphorus ethyl, tungsten sand, tin ore, tantalum, niobium ore and other non-ferrous metals, rare mineral metals and non-ferrous metal minerals with gravity difference from fine materials with Granularity of 0.3-0.02mm. Measurement of  spiral chute

spiral chute

The difference between energy-saving bal

The difference between energy-saving bal The drawbacks of difficult selection and

The drawbacks of difficult selection and Introduction to the characteristics of d

Introduction to the characteristics of d Types of mining magnetic separation equi

Types of mining magnetic separation equi What is the price of the Hesha magnetic

What is the price of the Hesha magnetic  The dry magnetic separator is applicable

The dry magnetic separator is applicable The price of dry magnetic separators is

The price of dry magnetic separators is  Selection range of fly ash magnetic sepa

Selection range of fly ash magnetic sepa Magnetic field intensity division of mag

Magnetic field intensity division of mag Different factors affecting the price of

Different factors affecting the price of How to achieve better magnetic separatio

How to achieve better magnetic separatio Industrial types and requirements of man

Industrial types and requirements of man Cement grinding process flow of ball mil

Cement grinding process flow of ball mil Optimization and Improvement of Wollasto

Optimization and Improvement of Wollasto Production process and main equipment of

Production process and main equipment of Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete equipment for quartz sand benef

Complete equipment for quartz sand benef Complete equipment for graphite ore bene

Complete equipment for graphite ore bene Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete set of mining beneficiation equ

Complete set of mining beneficiation equ Complete energy-saving beneficiation equ

Complete energy-saving beneficiation equ Complete set of manganese ore beneficiat

Complete set of manganese ore beneficiat Gold selection complete equipment

Gold selection complete equipment Complete beneficiation equipment

Complete beneficiation equipment Complete set of sand gold beneficiation

Complete set of sand gold beneficiation  Complete set of Baryte beneficiation equ

Complete set of Baryte beneficiation equ Complete beneficiation equipment for cop

Complete beneficiation equipment for cop Complete set of iron ore equipment

Complete set of iron ore equipment Complete machine for iron ore beneficiat

Complete machine for iron ore beneficiat Complete beneficiation production line

Complete beneficiation production line